| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

|---|---|

| Incoterm: | FOB,CFR,CIF,FCA,CPT |

| Min. Order: | 1 Kilogram |

| Delivery Time: | 15 Days |

Basic Info

Model No.: Ta Bar-30

Shape: Lump

Concentrate or Not: Non-concentrate

Forging Product: Cold Rolling Feature

Additional Info

Packaging: wooden case

Productivity: 1ton/month

Brand: SYMT

Transportation: Ocean,Land,Air

Place of Origin: Shaanxi, China

Supply Ability: 10 Tons per Month

Certificate: ISO9001

Product Description

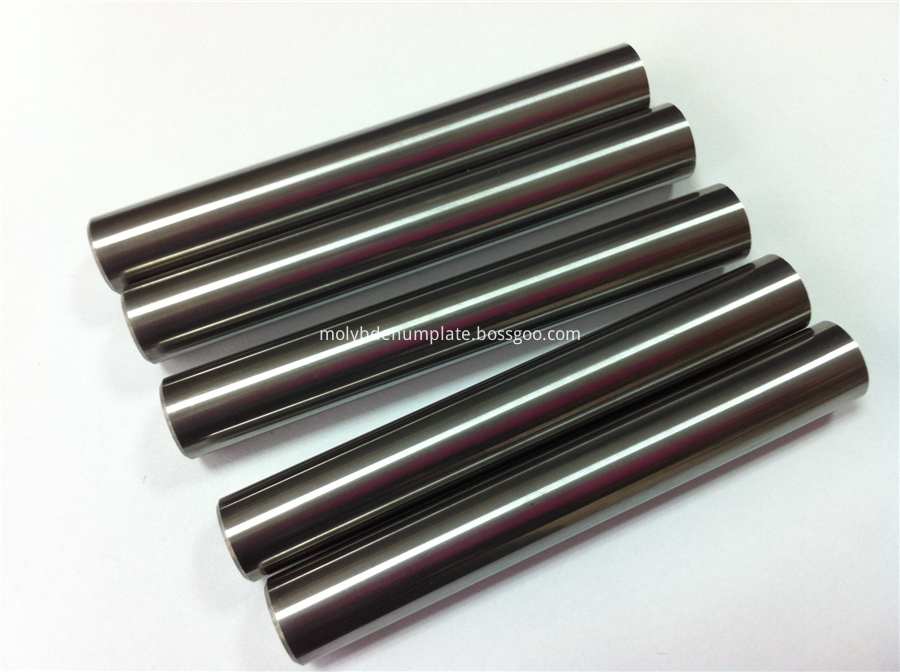

ASTM B365 Pure Tantalum Bar

Tantalum bar has widely use in different area , especially in heavy industry producing and Vacuum furnace manufacturing, our pure tantalum bar is made of 99.95% and 99.99% pure tantalum material , which garantee the quality of our products.

1. Grade: Ta1, Ta2, TaNb3, TaNb20, Ta2.5W, Ta10W

2. Refractoriness: Above 2000

3. Different sizes are available

4. We can provide all kinds of Tantalum Rods just on per client's requirements

5. The tables under will help you understand our products

Table1. tantalum bar Chemical composition:

|

Chemistry % |

|||||||||||||

|

Designation |

Chief component |

Impurities maxmium |

|||||||||||

|

Ta |

Nb |

Fe |

Si |

Ni |

W |

Mo |

Ti |

Nb |

O |

C |

H |

N |

|

|

Ta1 |

Remainder |

|

0.004 |

0.003 |

0.002 |

0.004 |

0.004 |

0.002 |

0.03 |

0.015 |

0.004 |

0.0015 |

0.002 |

|

Ta2 |

Remainder |

|

0.01 |

0.01 |

0.005 |

0.02 |

0.02 |

0.005 |

0.08 |

0.02 |

0.01 |

0.0015 |

0.01 |

Table3. Mechanical requirements (annealed condition)

|

tantalum Rod, Diameter 0.125" (3.18mm)~2.5" (63.5mm) |

|||

|

Grade |

Tensile strength, psi (MPa), ≥ |

Yield strength, psi (MPa), ≥ |

Elongation in 1 inch gage length, %, ≥ |

|

RO5200/RO5400 |

25000 (172) |

15000 (103) |

25 |

|

RO5252 |

40000 (276) |

28000 (193) |

20 |

|

RO5255 |

70000 (482) |

55000 (379) |

20 |

|

RO5240 |

40000 (276) |

28000(193) |

25 |

tantalum bar and tantalum alloy bar Dimensions and tolerances

|

Designation |

Producing way |

Diameter d(mm) |

Diameter and side Length tolerance(mm) |

Length |

Length tolerance |

||

|

Forging |

Rolling |

Sanding or machining |

|||||

|

Ta1Ta2 |

grinding Machining |

3.0~4.5 |

±0.05 |

±0.05 |

- |

500~1500 |

±5 |

|

>4.5~6.5 |

±0.10 |

±0.10 |

- |

500~1500 |

±5 |

||

|

>6.5~10.0 |

±0.15 |

±0.15 |

±0.15 |

400~1500 |

±5 |

||

|

>10~16 |

±1.5 |

±0.20 |

±0.2 |

300~1500 |

±5 |

||

|

>16~18 |

±2.0 |

- |

±0.2 |

200~1500 |

±20 |

||

|

>18~25 |

±2.5 |

- |

±0.3 |

200~1500 |

±20 |

||

|

>25~40 |

±3.0 |

- |

±0.4 |

150~1500 |

±20 |

||

|

>40~50 |

±3.5 |

- |

±0.5 |

100~1500 |

±20 |

||

|

>50~65 |

±5.0 |

- |

±0.6 |

100~1500 |

±20 |

||

|

>65~100 |

±5.0 |

- |

±0.8 |

100~1500 |

±20 |

||

|

Note |

The way of sanding and machining will be decided by the required diameter tolerance |

||||||

2. Process

We handle every stage in the manufacture of our products inhouse. From the raw materials through to the finished tantalum bars: including the development of new materials. In this way, we can guarantee that you benefit from the very best quality.

3. Technical condition

GB/T14841-93 (Chinese standard for tantalum bars)

ASTM B365-92(American standard for tantalum bars, rods)

4. Packaging

Standard individual packing: depending on their size, the sheets will be either packed individually or in parcels with paper between the different pieces.

Features

1. High melting point

2. High-density

3. High temperature oxidation resistance,

4. Long service life

5. Resistance to corrosion

Application

Chemical industry, electronic industry, aerospace industry, aviation industry, capacitors, high temperature furnace parts, semiconductor, sputtering targets and relative devices and is widely applied to electronics, metallurgy, chemical, pharmacy, aerospace and other fields.

Contact Person: Sarah jia

Phone:86-917-3906882

Fax:86-917-3906880

Address: Block A, Fortune Building, Gaoxin Avenue,Baoji,Shaanxi

Sweep wechat

© 2019 CHINA WAY. All Rights Reserved. Baoji Shengyuan Metal Material Co., Ltd., Inc. All rights reserved. site map. sitemap.html